A range of technologies as close as possible to the manufacturers requirements

Energy efficiency

Energy efficiencyUsing less lowers the environmental impact of production and reduces production costs.

Reliability

Eliminating machine stops for maintenance thanks to the through-type silencer (anti-clogging) used in vacuum pumps, helps increase productivity of packaging lines.

Flexibility

Enabling a product to adapt itself to your production helps provide fl exibility and reactivity.

Very high output

Combining suction cups and pumps developed specially for very high outputs, to meet the expectations of the most demanding customers.

Ergonomics

Accelerate the handling and use of products making operators more versatile.

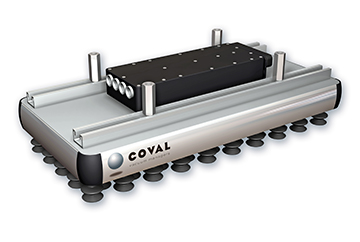

Integrates all the functions (control valve, pressure regulation, ‘product gripped’ control thanks to the vacuum switch) in a single compact and light module. The vacuum pump is placed closer to the suction cups, reducing the cycle duration and limiting energy loss during handling.

Integrates all the functions (control valve, pressure regulation, ‘product gripped’ control thanks to the vacuum switch) in a single compact and light module. The vacuum pump is placed closer to the suction cups, reducing the cycle duration and limiting energy loss during handling.

Whatever the pressure supplied by the compressed air network (between 4.5 and 7 bar), this is automatically optimized by ASR to 3.5 bar and generates energy savings of 40% on average. ASR technology avoids the need for an external pressure regulator and eliminates the risk of altering settings and of unnecessary consumption.

Whatever the pressure supplied by the compressed air network (between 4.5 and 7 bar), this is automatically optimized by ASR to 3.5 bar and generates energy savings of 40% on average. ASR technology avoids the need for an external pressure regulator and eliminates the risk of altering settings and of unnecessary consumption.

Located in France, second exporting country of food processing products in the world, COVAL has a continued

Located in France, second exporting country of food processing products in the world, COVAL has a continued.jpg) Compatible with numerous materials : cardboard, glass, hard and soft plastic, flow pack…

Compatible with numerous materials : cardboard, glass, hard and soft plastic, flow pack… .jpg) - Flexible, high speed suction cups, MVS series

- Flexible, high speed suction cups, MVS series The universal FlowPack suction cup.

The universal FlowPack suction cup. Plug & Play installation, very compact, wide range with many accessories, optimal ergonomics for adjustment, operation, maintenance.

Plug & Play installation, very compact, wide range with many accessories, optimal ergonomics for adjustment, operation, maintenance. Plug & Play installation, very compact, wide range with many accessories, optimal ergonomics for adjustment, operation, maintenance.

Plug & Play installation, very compact, wide range with many accessories, optimal ergonomics for adjustment, operation, maintenance. The GVEC series "Easy Clean" vacuum pumps have been designed to meet the needs of vacuum handling applications in industries whose production requires frequent cleaning, particularly in the food-processing sector.

The GVEC series "Easy Clean" vacuum pumps have been designed to meet the needs of vacuum handling applications in industries whose production requires frequent cleaning, particularly in the food-processing sector. Vacuum pump with fieldbus communication (EtherNet/IP, CANopen or PROFINET):

Vacuum pump with fieldbus communication (EtherNet/IP, CANopen or PROFINET):