AEROSPACE ENGINEERING SOLUTIONS

For over 30 years, COVAL supplies the different companies involved in the Aerospace industry with comprehensive management of vacuum handling for the manufacturing process as a whole: lifting, moving and clamping of plane parts.

COVAL solutions, such as vacuum pumps and suction cups, equip all the tooling used in the process of manufacturing, machining and assembly of the different sections that make up an aircraft.

The numerous processes required by the aerospace industry need technical skills, expertise, innovation, and service. To meet these challenges, COVAL relies on:

A strong capacity for development and innovation

A team 100% dedicated to the Aerospace industry

A full product range integrating mechatronics for better productivity « Fully integrated » vacuum solutions

Compliance with the strictest quality standards

Presence in economic areas with strong potential, thanks to 5 subsidiaries.

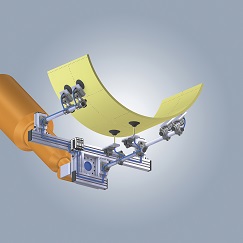

Integration of our vacuum solutions for robots:

Integration of our vacuum solutions for robots: Specific clamping solutions for machining processes:

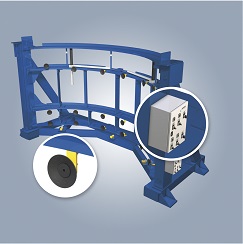

Specific clamping solutions for machining processes: Vacuum clamping of plane parts on assembly jigs:

Vacuum clamping of plane parts on assembly jigs:

●Taking parts at high speed from a drawing press line.

●Taking parts at high speed from a drawing press line.